Products & Services » Mold Tooling

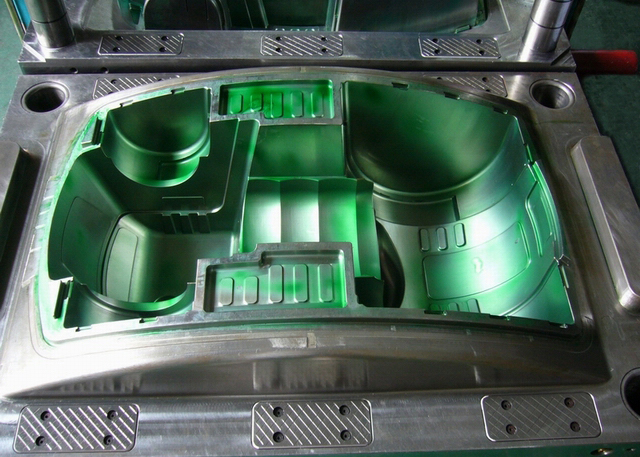

We have built more than 250 molds for our customers and pride ourselves on our ability to optimize part and mold design at the beginning of a project before the steel is cut. We can accept virtually any electronic design database including Solidworks and Pro-E, and our engineers will help customers with suggestions on part design that will improve quality and reduce costs. Our facilities are outfitted with state-of-the-art, highly automated machines with full CAD/CAM capabilities.

We place great emphasis on mold design to ensure that, in combination with our tool building expertise, we can produce a mold that will meet all of your expectations. Our experience guarantees that every mold built through CCM will produce quality parts at the quoted price. We have the capacity of making over 6000 tools per year, and our tooling lead time is around 4 to 8 weeks.

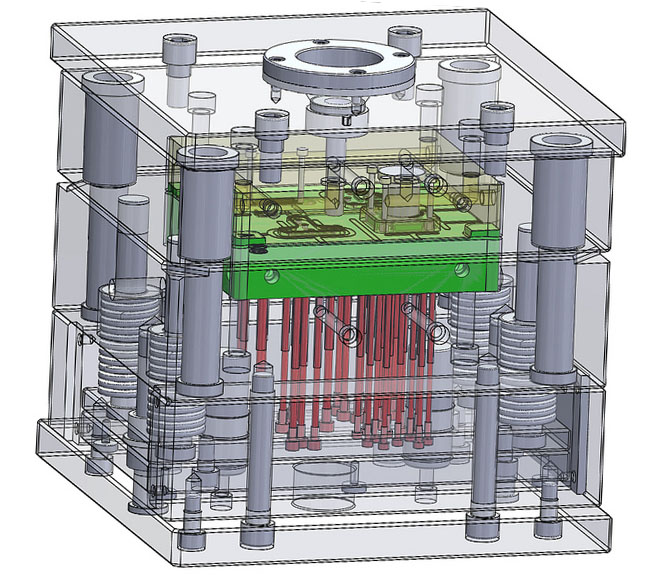

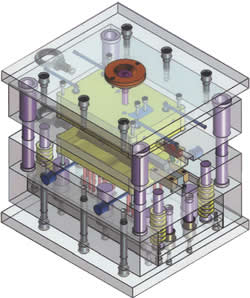

Tooling Facility:

- CAD/CAM/CAE center

- 13 sets of CAM machines

- 30 sets of EDM & wire cut machines

- Die and spotting press

- Precision electrical spark machines

- Manufacturing center

- Precision straddle type matched mould machine

- CNC copy milling machine

- Mold workshop

- EDM workshop

- Numerical control workshop

- 3-coordinate measuring machine